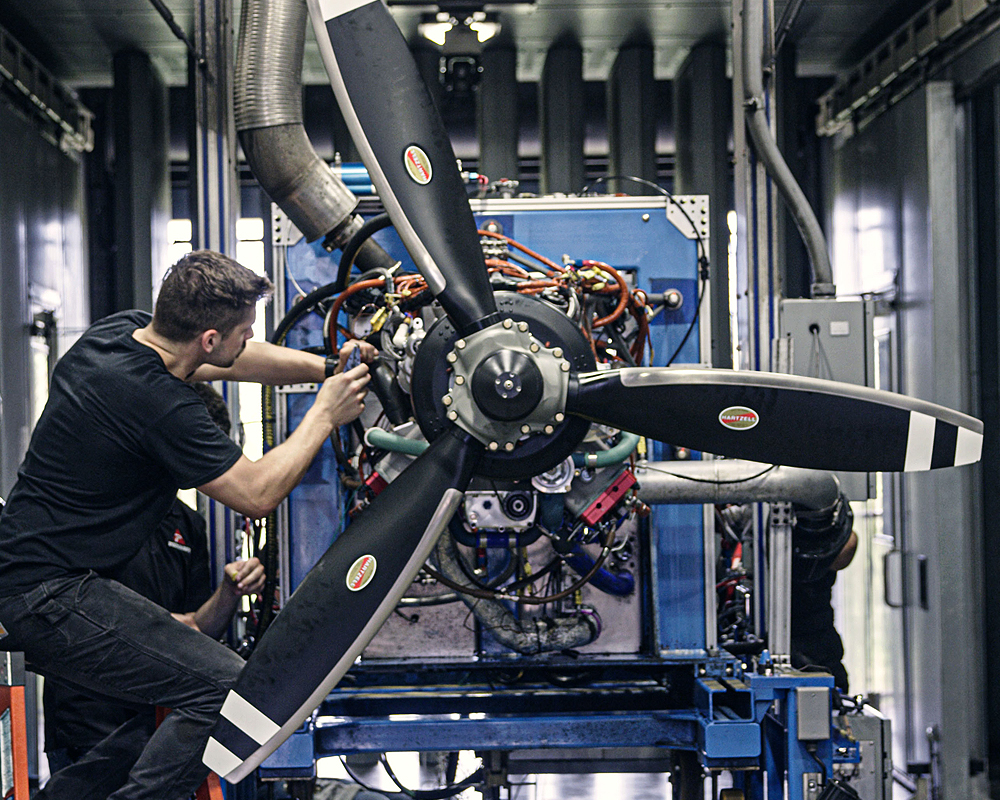

(Racine, Wisconsin) With FAA Type Certification of its revolutionary new DHK180 piston-engine complete, and reservation deposits now being taken, DeltaHawk Engines, Inc. is moving towards production– with initial deliveries of customer engines planned for 2026.

The jet fuel burning, 180-horsepower DHK180 is the first of a family of engines to come from DeltaHawk and offers ease of operation, high fuel efficiency, reduced maintenance, and superior altitude performance compared to traditional aircraft piston engines. The company has received extraordinary interest in the new engine from a broad range of aircraft OEMs and experimental kit manufacturers, as well as individual pilots and commercial operators. The DHK180 was also recently chosen by NASA for their Subsonic Single Aft Engine project, known as SUSAN, and has been selected by Ampaire for a hybrid proof-of-concept aircraft as well.

Additional endurance testing and flight evaluations in multiple aircraft are underway while preparing for production and commercial sales. Production parts are also beginning to enter the supply chain process. In addition, DeltaHawk has just announced its factory warranty program – which will cover 24 months or 2,000 hours, whichever comes first. The new warranty can also be extended to 36 months or 2,400 hours if an operator agrees to provide timely engine monitoring data and oil analysis – an industry-leading option.

Engine deliveries for both certified and experimental aircraft will include firewall-forward installation packages for specific aircraft. Packages for selected aircraft are now under development and final pricing will be announced soon. DeltaHawk is also actively seeking industry partners with engine installation STC experience to augment our own capabilities.

Field service for the new engine will be available through a planned network of qualified service providers which the company is actively recruiting. All factory authorized DeltaHawk service facilities will be supported by the company’s in-house experts, as well extensive on-line training programs that will allow remote training worldwide, including certification. Those training programs will be available later this year.

Because of its truly clean-sheet design, development and certification of the new DHK180 has taken a significant amount of time and investment. However, once the true benefits of the engine are experienced by pilots, it is widely believed DeltaHawk’s design will soon be considered the benchmark of what a modern general aviation piston-engine should be.

The Whole Story Return to News Return to Events